Changing the paradigm:

Eckhaus Latta x unspun at NYFW SS24

Making the first 3D woven pants

A revolution in manufacturing has never looked this good. To introduce 3D weaving to the world, we tapped Zoe Latta of the the world-class fashion house Eckhaus Latta to experiment with its capabilities. With an unprecedented technology, we wanted to set the pace for the future of apparel.

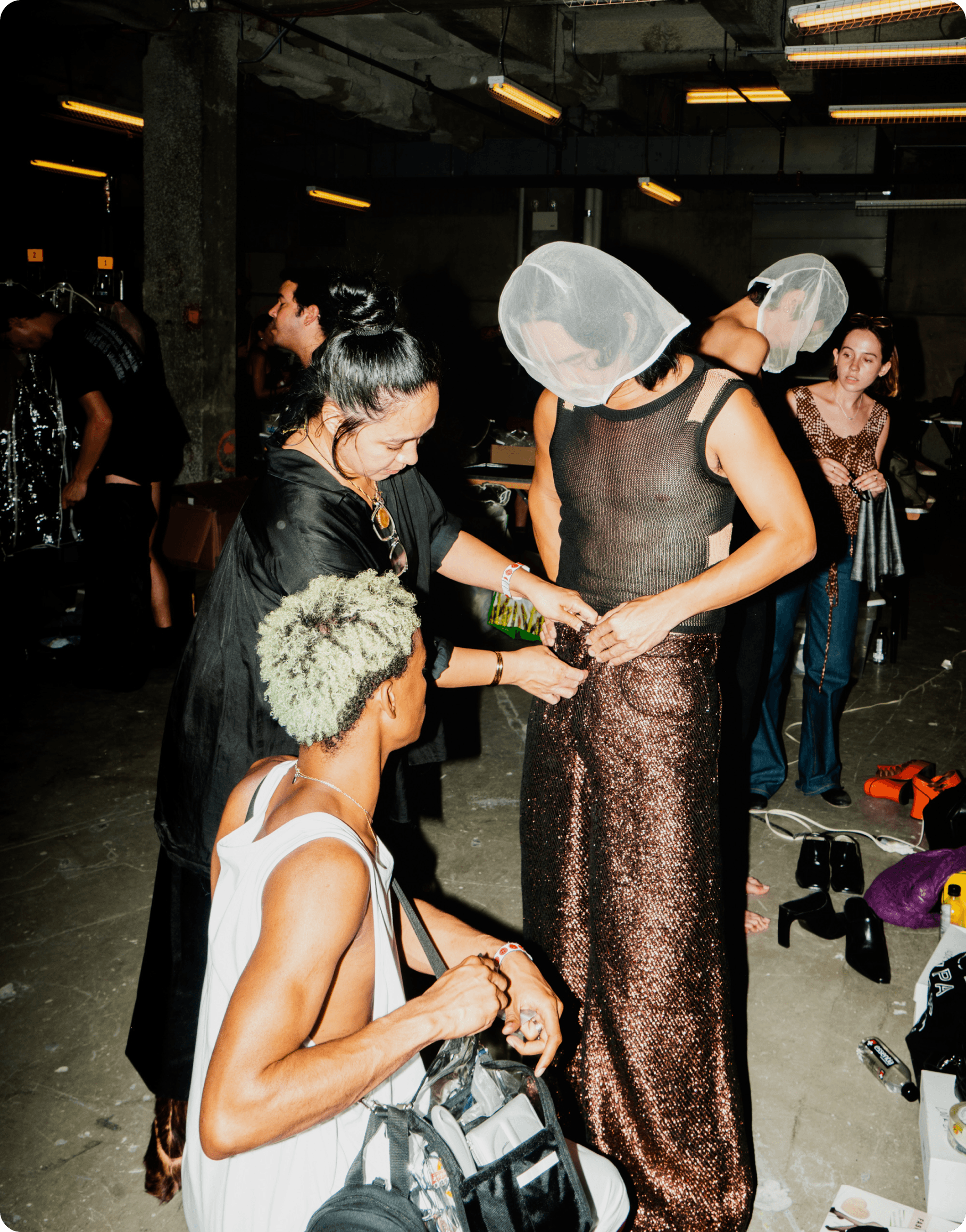

Working side by side at our Oakland microfactory in the Spring of 2023, Latta and unspun CPO Beth Esponette built on a concept for wide leg pants with an array of fibers. As novel as it was rapid, above all else, designing a garment with Vega, unspun’s 3D weaving platform, was fun.

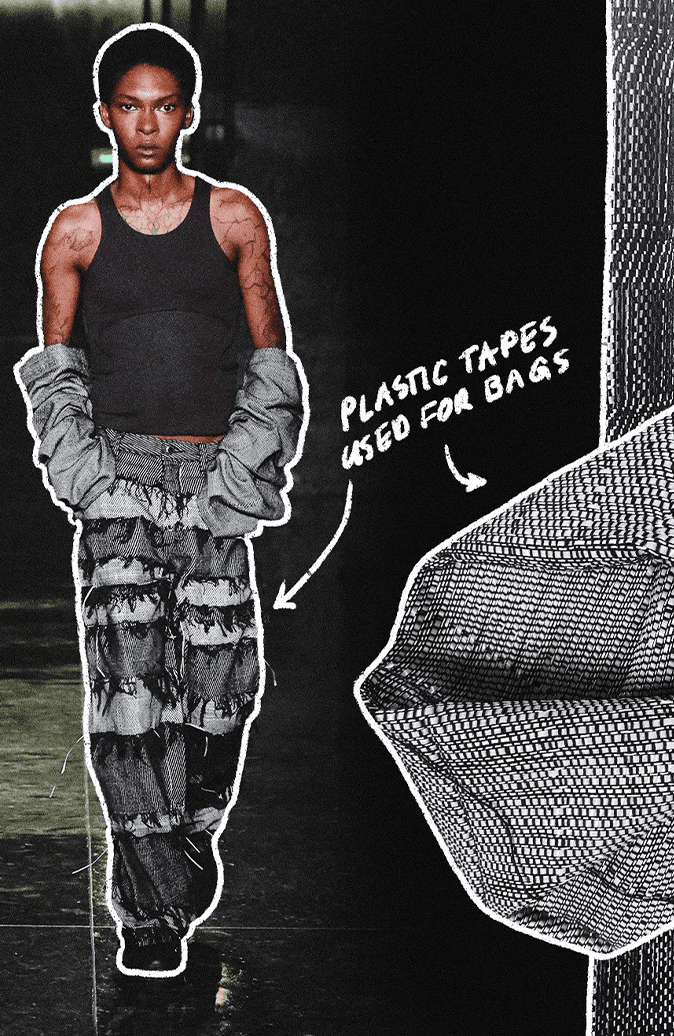

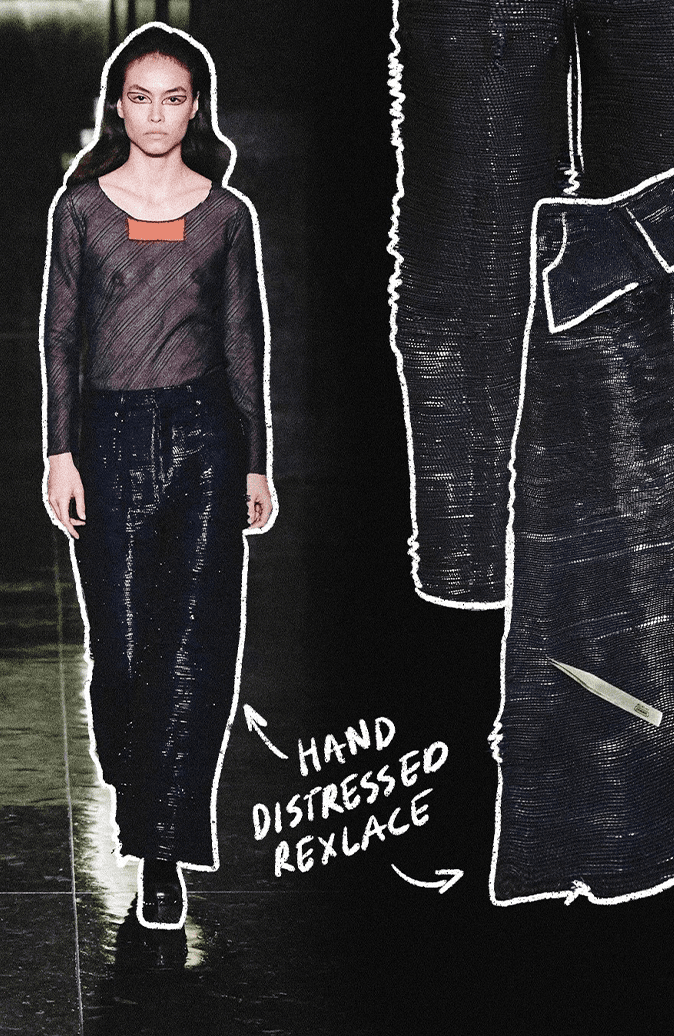

To begin, our teams settled on two pant styles, a standard wide and ultra-wide. From there, we tested how different materials —cotton, Rexlace, and jute twine among them— would translate into the wide leg silhouette. Through our Vega UI, we programed a variable twill pattern to be woven with a narrowing diameter. Then, in minutes, our Vega machine wove thousands of yarns into a single, seamless pant leg. For taking so little time to make, we were able to iterate each design within hours. By the end of a few days, we had five pairs of pants ready for the runway.

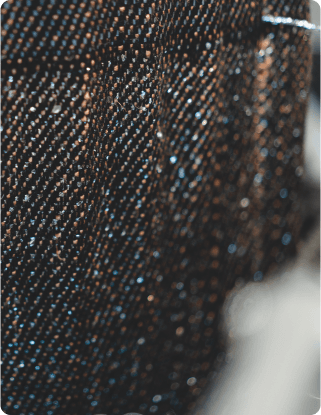

Of the pants we debuted in September, two styles are on sale through our Shop and at select stockists. In keeping with the Eckhaus Latta aesthetic, one is made with a white plastic tape à la Ikea bags, the other a specialized metallic yarn. All pieces have been 3D woven with Vega in California. First-rate and first-of-its-kind.

Eckhaus Latta advances sartorial expression with unique materials, and unspun facilitates clothing design with 3D weaving, to push the boundaries of fashion.

A sense of play combined with a new tool kit equals more inventive apparel.

We made a collection of clothes for the season. We launched a new category of clothing for the century.

3D weaving inaugurates an era of faster production, simplified logistics, and greater creative possibility in the fashion industry.

Eckhaus Latta

In the twilight zone between fashion and art, Eckhaus Latta brings curiosity to bear. Motivated by the principle of resourcefulness, the label is adept at revealing some essential quality of the unused and unexpected —vintage textiles and other items its competitors overlook— with which it constructs clothes. Here, fabric becomes texture, and an article of clothing becomes sculpture; a story seems to emanate from its very materiality. This artistic acuity toward apparel guides how Eckhaus Latta regards the person who wears apparel, as a physical self interacting with an object. At its best, a piece from the label will adorn their figure while revealing something about who they are.

What our partnership shows

3D weaving is an ultraefficient manufacturing method

Vega™, our 3D weaving platform, outputs pant legs in a matter of minutes, increasing the speed of garment production by an order of magnitude. Moreover, because it accommodates both the design and production of a garment in one location, Vega™ dramatically accelerates product development while obsolescing entire stages of the conventional fashion industry supply chain.

A Vega™ machine can make pieces of clothing using many materials

A Vega™ machine can operate near the point of sale

A Vega™ machine can weave continuous jacquard patterns

We’ve built the tech, proved it works, and are ready to partner with the world’s most innovative brands.

Let's revolutionize fashion, together.

Learn more about our

Impact

Process

Vision

Stories